KITCHEN

Our warranty is valid for 2 years from the date of purchase and covers all manufacturing defects. The warranty period enters into force from the date printed on your receipt or sales slip. You may be asked to present proof of purchase when requesting service. The warranty is non-transferable and is valid only for the original purchaser. It covers repair or replacement of unusable or defective parts free of charge during the warranty period after inspection and acceptance by Poliform or its agent. Natural variations in the colour of the wood, changes in colour under ambient or artificial light, slight variations in dimensions owing to high humidity or dry conditions and the grain of wood, knots or other natural characteristics of wood products are not covered by the warranty. The warranty excludes damage resulting from careless or incorrect furniture installation, potential damage from accidents such as that resulting from a fall, impact, natural disaster, fire and, in any case, all defects that cannot be attributed to defects in the manufacture of the product. Moreover, the warranty is not valid in the event that our products are disassembled, modified or repaired by anyone other than authorised Poliform personnel. Damage due to poor upkeep or improper use of the product are not considered defects of manufacture. You will find useful recommendations in the instruction booklet regarding the use and care of your product. If you have any doubts or require further information, consult the Poliform reseller where your product was purchased. For any situation not expressly covered by this warranty legal provisions in force shall apply.

The carcasses of the cabinets are composed of wood water-repellent particles panels V100, thickness 18 mm, coated with non-scratch melamine resins, easy to clean, with minimum emission of formaldehyde EPF-S E0,5 (in accordance with the limits set out by the us regulation TSCA and CARBN PHASE 2).

For the other elements we use particle board panels in class EPF-S E0,5 or particle board panels in class E1, anyhow fully aligned with the limits set by conforming to eu standards EN120 and EN-717-2 with respect to formaldehyde release. With respect to varnish, Poliform exclusively use polyurethane coatings free of heavy metals and volatile organic compounds (VOC) belonging to the various classes within table A1 of the italian ministerial decree of 12 july 1990 and/or classes I and II within table d of the italian ministerial decree of 12 july 1990.

Subcortical tree trunk sections nearest the darker innermost annual rings, also known as duramen. Heartwood is considered to be high-quality, genuine natural wood in contrast to wood panels made from wood particles or multilaminates.

Panel composed of wood particles with a thin layer of solid wood, called a peeling, about 7mm thick.

Wood-based panels made from wood particles (shavings, wood chips, etc.) The wood particles are held together with hardening synthetic resin and then heat pressurised. Particle board panels use an assortment of less costly wood which is generally the by product of other processes: this is why this type of product is of interest from an ecological standpoint.

A panel composed of wood particles and covered with a cellulose base material (paper), sheets of polymer (pvc veneer, abs, etc.) or melamine resins.

A hardening synthetic resin obtained from polycondensation of formaldehyde. It is a colorless, odorless resin that is resistant to water, chemicals, abrasion and heat and which has particular transparency under light

(Acrylonitrile butadiene styrene) a synthetic thermosetting plastic resin with good resistance to acids. It repels dust and cannot warp. For these reasons, abs is used in the manufacture of edges and sheets for surface coating.

Panels of polyesterized chipboard lacquered on both sides with polyurethane polymer-based paint having a high molecular weight. The panels have the characteristics of being dimensionally stable and water resistant.

Common glass is composed almost exclusively of silica, the same substance as quartz. In its purest state, glass is transparent, relatively hard, almost inert from a chemical and biological standpoint and presents a very smooth surface. Glass is available in a wide range of finishes and colors for interior decoration. It is possible to circumvent its intrinsic fragility by using chemical treatments (adding other minerals to the compound) or physical processes, such as tempering.

Glass submitted to the tempering process which consists in the brusque cool down during the manufacturing. The slab obtained has huge internal tensions and is characterized by hardness and high fragility. In case of breakdown the tempered glass splits up in non cutting plinters.

A silvery, highly ductile metal. Its chief properties are resistance to corrosion, tensile strength and its light weight. These properties are ideal for manufacturing durable yet lightweight frame components. Raw aluminum can be worked using several different processing techniques such as fusion, forging or pressing.

Marble is a metamorphic rock composed mostly of calcium carbonate (caco3). Marble results from the metamorphism of sedimentary rock, a process that causes complete recrystalization of calcium carbonate. Marble’s color depends on the presence of mineral impurities (clay, silt, sand, iron oxides, flint nodules) present in grains or layers inside the original sedimentary rock. White marble is the result of the metamorphism of calcite rock containing no impurities.

Quartz agglomerate is a material that is produced in the form of slabs measuring 304×140 cm using Bretonstone® System Technology and a special vacuum vibro-compression process. The slabs are achieved by mixing siliceous sand or pure quartz (95%) with a polyester structural resin (5%) and coloured pigments stablised using uv rays.

AISI 304 (reference name used across the world). This is an austenic stainless steel containing between 18% and 20 % chromium and between 8% and 10 % nickel, a composition which gives the material improved resistance to corrosion and superior workability.

Dupont Corian® is a solid, non-porous, homogeneous surfacing material composed of ± 1/3 acrylic resin (also known as polymethyl methacrylate ) and ± 2/3 natural minerals. The main mineral is aluminium trihydrate (ath) derived from bauxite, an ore from which aluminium is produced.

Dupont Corian® is an inert and nontoxic material. Under normal temperature conditions, it does not emit gases. When burned, it releases mainly carbon oxides and the smoke generated is optically light and does not contain toxic halogenated gases.

Dupont Corian® can be thermoformed in wooden or metal moulds at controlled temperatures in order to create various 2d and 3d design objects. Embossing effects can also be created using the bas relief technique.

Dupont Corian® is manufactured in compliance with strict standards in order to limit waste and energy consumption at all stages of the production process. Both the material itself and the adhesives and sealants used to install it are green guard indoor airquality certified as producing low VOC emissions.

The high pressure laminates are composed of layers of cellulose fibres (normally paper) soaked in thermohardening resin, joined through a process that consist in the combined action of heat and high pressure and that implies the polycondensation of the thermohardening resin. The material obtained is homogeneous, not porous and can be covered with the required finishing.

Generally more than 60% of HPL is composed of paper and the remaining 30-40% is represented by polymerized synthetic thermohardening resin: phenolic resin for the heart of the panel and aminoplast resine for the decorative surface. These belong to the group of the thermohardening resins that interact in irreversible manner through chemical ties that are formed during the process of polymerization. The high presure gives life to a steady and non reactive material, which characteristics are completely different from those of the initial components.

The hpl is supplied in panels of various dimensions, thickness and with different finishings.

It is an innovative material produced through high pressure thermo-lamination.

The external surface involves the use of nanotechnology and its decor is obtained through new generation resins.

This laminate has an extremely matt surface, it is anti-fingerprint, soft touch.

Poliform recommends that you do not dispose of your product in the outdoors. Because of our manufacturing technology and the routine use of recyclable materials, discarded Poliform products can be re-used in the manufacturing process. For this reason, drop off your Poliform product at the waste disposal centres within your municipality.

To facilitate the collection, reuse, recovery and recycling of packaging, we inform you that the packaging is composed as follows: PAP20 carton, PS 06 polystyrene, FOR 50 wooden boxes, Profiles in Systempack PELD 04.

The following instructions, broken down by material, provide the best recommendations for preserving your Poliform kitchen for years to come. Use only recommended cleaning products and avoid harsh or abrasive detergents: proper care will enable you to enjoy Poliform quality for many years.

The worktop in DuPont Corian® is extremely hygienic since it is non porous. Although liquids cannot penetrate corian, it is best to wipe up spills as they occur. Just use a damp cloth and a mild cream abrasive cleanser or a common household degreaser (E.G. Jif, bar keepers friend). Always clean using a circular motion.

For stains caused by liquids such as vinegar, coffee, tea, lemon juice, dyes, ketchup, red wine or vegetal oils first, try the easy methods, then progress with an abrasive plastic scouring pad and a detergent or an ammonia based hard-surface cleaner. Only with a really persistent stain as lily pollen, or saffron, or with a light scratch, should you need to resort to an abrasive plastic scouring pad and rub over the stain with some bleach. Rinse several times with warm water and dry with a soft cloth. Always restore the overall luster afterwards, using a damp cloth and a mild cream abrasive cleaner and blend the scrubbed area into the entire surface by rubbing in a circular motion.

Always use a heat protection pad, trivet (with rubber feet) or protective sink mat for hot cookware, or leave cookware to cool on the hob first. Never put hot pans, particularly cast iron, directly on a corian top. Such heat can damage any surface. Always use the correct size pan on the burner and place it centrally. An overhanging pan scorches surrounding surfaces.

Never cut or chop on the corian work surface dark, heavily pigmented colours will show scratches, dust and ordinary wear and tear more readily than lighter, textured colours. Accidental spills of strong chemicals (E.G. Paint stripper, brush cleaners, metal cleaners, oven cleaners, cleaners containing methylenechloride, acid drain cleaners, acetone-based nail varnish removers etc.) Should be flushed promptly with plenty of soapy water to avoid damaging worktops. Corian is inherently “renewable” because it is solid and homogeneous all the way through. Most damage, including severe impact, heat or chemical damage, can usually be repaired on site to restore the original, smooth, hygienic solid surface integrity.

Clean with lukewarm water and neutral soap using a cloth or sponge. Marble is a material that must be cleaned with extreme care: being porous it can absorb liquids resulting in stains. Poliform surfaces are treated with a special anti-stain and anti-oil product; but it is fondamental to clean immediately the “fresh stains” of coloured liquids and to avoid the use of acid liquid detergents. For the preservation of the surfaces it is recommended to execute the treatment with liquid or water-repellent wax for marble every 2 months. In case of particularly dirty surfaces use proof oil, a natural treatment for marbles recommended by Poliform.

Absolutely avoid abrasive or aggressive products: acidic detergents, bleach or steel wool. All our worktops are delivered with manual of use, maintenance and care.

The agglomerates of quartz are materials of high compactness and low asorbent power: they resist to acids, they do not absorb liquids, odors, and alimentary fats. They are simply to clean and guarantee the hygiene, they resist to a great number of daily use stains and daily domestic incidents like scratches and small hits. For the ordinary cleaning it is recommended to use neutral detergents and water, but it is fondamental to clean up the “fresh stains” immediately. In case of particularly dirty surfaces it is possible to use also aggressiv detergents containing acids like viakal and aiax bagno or orange clean, which is a natural detergent recommended by Poliform. Although the material can resist to high temperatures it is appropriated to protect it by using hot pads to avoid the direct contact with the burned pots or tableware.

All our worktops are delivered with ten year guarantee and with manual for use, maintenance and care.

For everyday cleaning, use water with neutral soap and a sponge or a cloth.

For detergent-resistant or long-time uncleaned stains, use a specific product, for example: cream detergents with abrasive particles.

Use vinegar diluted in abundant water or glass cleaning products. Warning: in case the glass is mounted in an aluminum frame, avoid alcohol or ammonia, which may damage the frame.

We recommend to use a soft cloth with lukewarm water for the cleaning of handles and other metal accessories, lacquered or oxidized. The use of abrasive sponges and/or aggressive cleaners containing alcohol or aggressive chemical agents could cause with the time deterioration of the visible surfaces and consequently detachment of the varnish or of the metal oxidation. The prolonged permanence of chemical agents on the surface like for istance: tomato juice, lemon juice, vinegar, salt or water and cleaners could start with the time a chemical reaction damaging the superficial quality of the items.

For a correct sliding of the parts in movement (drawers, hinges of the doors, extractors, etc.) Periodically remove the dust on the drawer slides and on the hinges with a soft and dry cloth. Lubricate with any product widely available on the market. Avoid any kind of abrasive cleaning product

Poliform recommends that you do not dispose of your product in the outdoors. Because of our manufacturing techology and the routine use of recyclable materials, discarded Poliform products can be re-used in the manufacturing process. For this reason, drop off your Poliform product at the waste disposal centres within your community

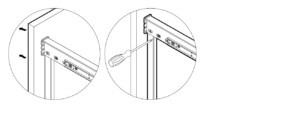

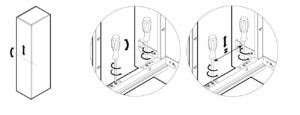

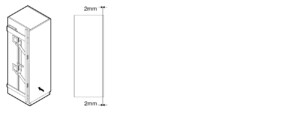

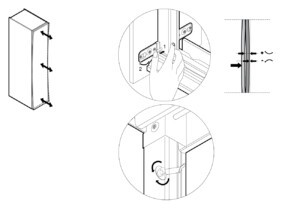

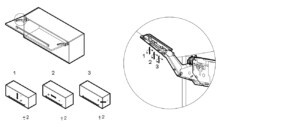

To remove them it is enough to starting from an end corner.

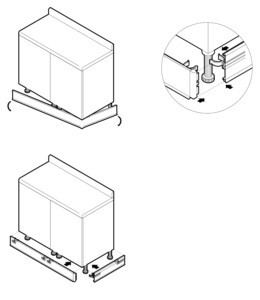

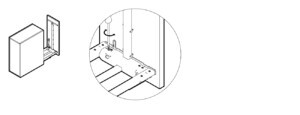

Lateral plinth. In case of lateral corners with lateral plinths, the corner junction is simply screwed to the frontal plinth.

Plinth re-hooking. Re-place the plinth making sure that they are well fixed to the feet.

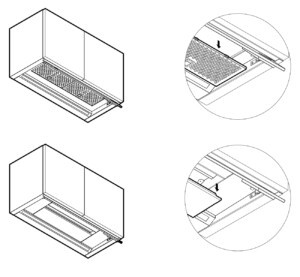

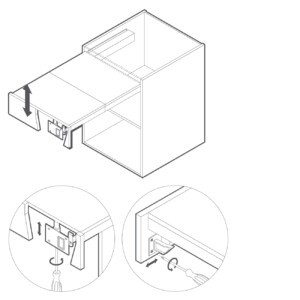

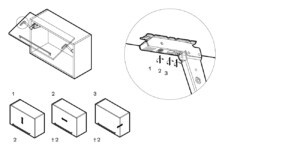

The filters of the recirculating hoods have to be cleaned periodically. In order to release them open the stopper pulling the lever in the middle of every filter.

Cleaning of the hood filters

You can wash the filters in the dishwasher using a standard program.

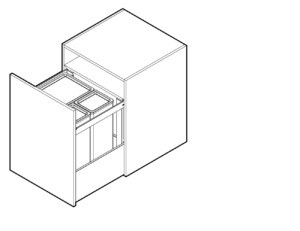

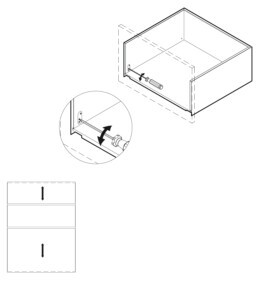

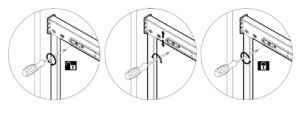

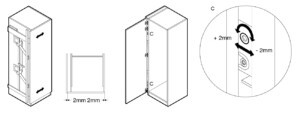

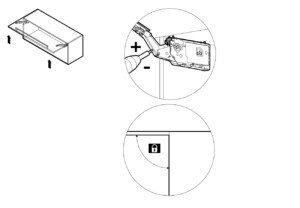

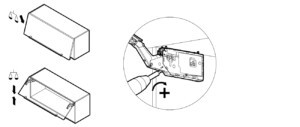

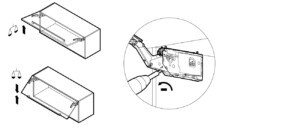

Make sure the adjustment blocks on the lid are in the minimum excursion position.

Open the extractor and make sure the lid castors are resting against the aluminium sides of the bin. If the distance between the adjustment block and the lid is 10mm, this means that when the extractor is in the closed position, the lid sits over the bin bags correctly. If you hear slight scratching sounds during the opening or closing of the extractor, raise the lid by adjusting the screws on the two adjustment blocks.

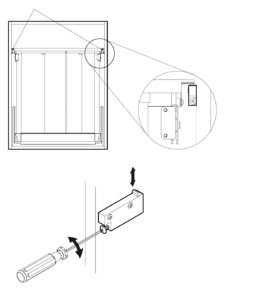

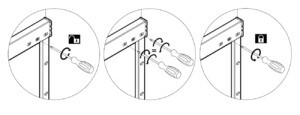

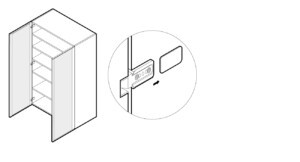

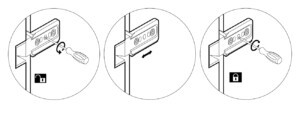

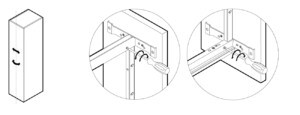

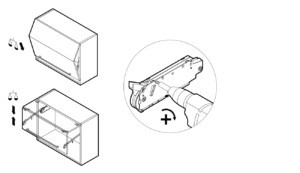

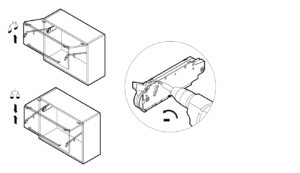

For vertical adjustment, act on the screw in the lower part inside the plastic block. For the horizontal adjustment act on the 4 screws indicated.

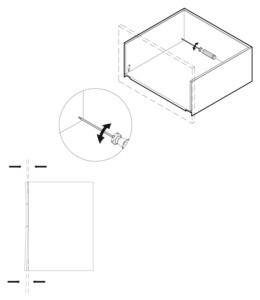

Blum lateral adjustment

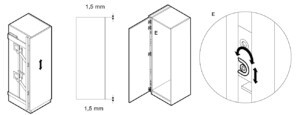

Adjustment limit: +/- 1.5mm

Caution: both sides need to be adjusted

Vertical adjustment

Adjustment limit: +/- 2mm

Adjustment limit:

Back panel k: +1.5mm/-0.5mm

Back panel k: +1.5mm/-0.5mm

Back panel c: +1.5mm/-1.5mm

Back panel f: +1.5mm/-1.5mm

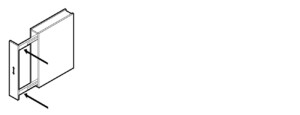

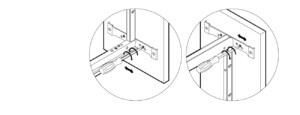

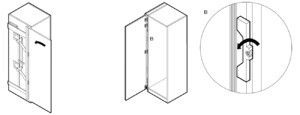

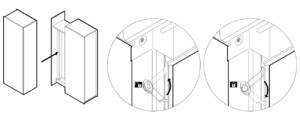

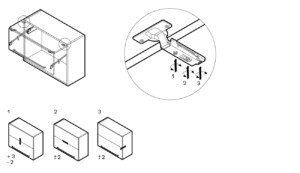

Door adjustment up-down

Attention: The adjustments must be done on the external side of the structure

Door adjustment right-left

Attention: the adjustments must be done on the inner side of the structure

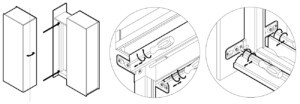

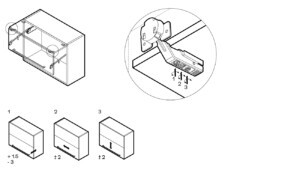

Adjustment of the horizontal rotation of the door

Attention: the adjustments must be done on the inner side of the structure

Adjustment of the vertical rotation of the door

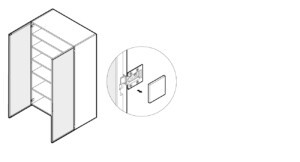

Junior Pantry

High – Low door adjustment

Levelling the door horizontally

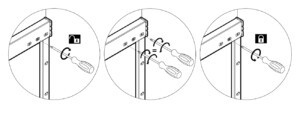

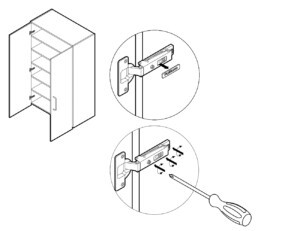

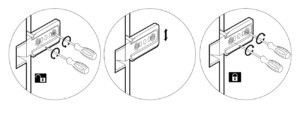

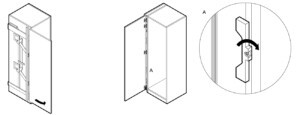

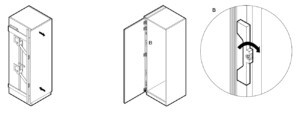

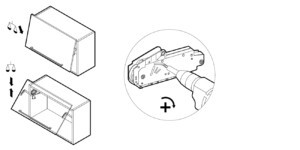

Remove the Poliform plate from the hinges inside of the unit (base/ tall/ wall unit). With a crewdriver it is possible to adjust the door in the 3 directions.

Remove the covering plate Following the procedure described below, the door can be adjusted in three directions.

Adjustment

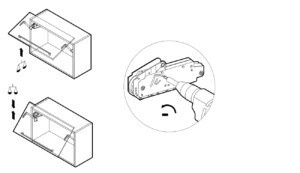

Remove the covering plate Following the procedure described below, the door can be adjusted in three directions.

Adjustments

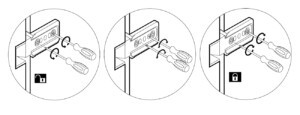

Adjustment -1.5 mm / +1.5 mm

Adjustment 0 mm / +1.5 mm

Adjustment -1.5 mm / +1.5 mm

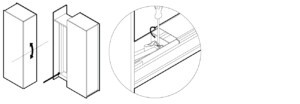

Disengage the block before making the adjustments

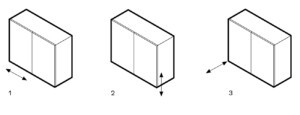

Door adjustment

Adjust the planarity of the door

Bring the door closer toward the bottom (D)

Detach the door from the top (B)

Adjust the door height

Lock/unlock of the door for adjustments

Door adjustment up – down

Door adjustment right – left

Adjust the screws in the same rotation direction

Adjustment of the rotation on the vertical axis of the door

Adjust the screws in the opposite direction of rotation

Adjustment of the rotation on the horizontal axis of the door

Adjustment of the evenness of the door

After the adjustment re-hook the door and check its evenness, otherwise repeat the operation

90° Opening stop

To adjust the door when falling act in this way.

To adjust the door when falling act in this way.

To adjust the frontal door act in this way.

To adjust the door when falling act in this way.

To adjust the doors when rising act in this way.

To adjust the frontal door act in this way.

To adjust the door when falling act in this way.

To adjust the doors when rising act in this way.

To adjust the alignment of the upper door when it falls, operate as indicated in the pictures. Upper hinge.

To adjust the alignment of the lower door when it goes up, operate as indicated in the pictures. Central hinge

Material: melamine-faced particles panels V100

Thickness: 18 mm

Finishing: light grey melamine called “perla” and dark grey melamine called lavagna

Frontal edge: ABS th.1mm in perla or lavagna

Sides edge: h.0.5 mm in perla or lavagna

Features: the bottom and sides of the sink base unit with leaf doors are clad with embossed aluminium to protect against water infiltration over time. In units for refrigerators, the bottom is made from 18mm thick phenolic birch plywood for added protection against water infiltration. The front panel is also clad with embossed aluminium.

Material: melamine-faced medium-density fibreboard.

Thickness: 8 mm

Finishing: melamine-faced in perla or lavagna

Material: aluminium

Thickness: 11,5 mm

Height: 70/100/120mm.

Max length: 3800 mm

Finishing: anodized aluminium, aluminium with brushed steel, embossed lacquered or metallic lacquered finish.

Features: special hooks allow easy removal to facilitate cleaning.

Material: black ABS

Diameter: 34 mm at centre – 70 mm at bottom

Height: 70/100/120 mm

Features: quick insert. Adjustment + 20 mm and – 5 mm

Hinge: in metal with quick-connect and three-way adjustment

Opening/closure: soft-close system with 110° opening. Corner rack units and plate rack units with 180° opening. The hinge has been tested for 80,000 opening/closing cycles.

Handles: applied metal handles or integrated metal and wooden handles.

Features: door levelling in vertical and in depth by the hinges.

Material: melamine-faced particle board

Thickness: 18 mm

Finishing: melamine-faced in perla or lavagna.

Frontal edge: ABS th.1 mm in perla or lavagna.

Sides edge: melamine th.0.5 Mm in perla or lavagna.

Support: metal

Features: the shelf includes an anti-tip mechanism

Material: melamine-faced particle board.

Thickness: 16 mm

Finishing: melamine-faced in lavagna.

Material: aluminium / painted steel

Thickness: 13 mm

Finishing: anodized aluminium / painted brown

Runners: the metal slides are manufactured by blum and made specifically for the legrabox type. They feature a Blumotion soft-close system and a safety catch to prevent drawers from accidentally falling off their slides. Each pair of slides has a capacity of up to 40kg and is tested for 100,000 opening/closing cycles. Certain types of pull-out baskets have slides with a capacity of 70kg per pair, tested for 80,000 opening/closing cycles. The slides are total extraction. The drawer and pull-out basket front can be adjusted in three directions. A black mat is inserted in the drawers and pull-out baskets.

Materia: metal

Features: these can be adjusted in height and depth directly from the inside of the unit. They are tested for a capacity of 125kg per pair.

Material: aluminium

Features: aluminum bars supplied with specific hardware with anti-tilt function.