-

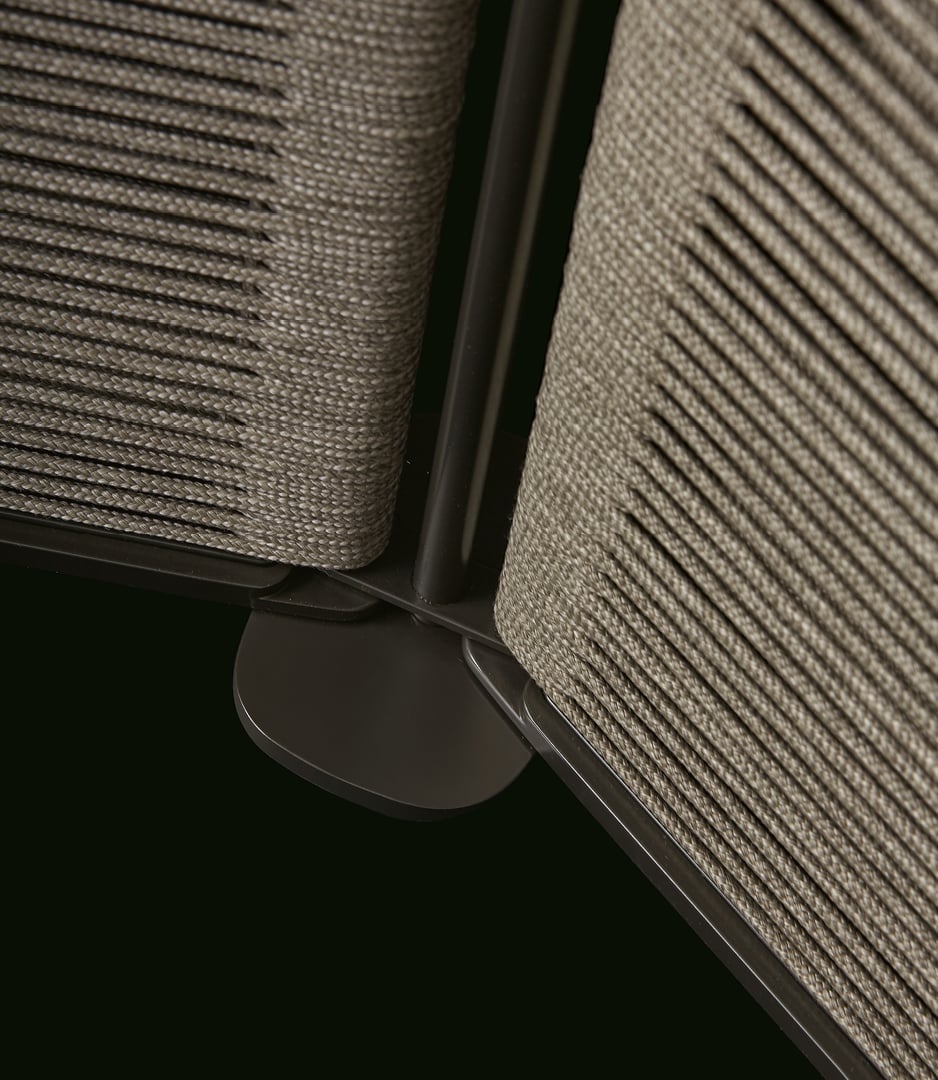

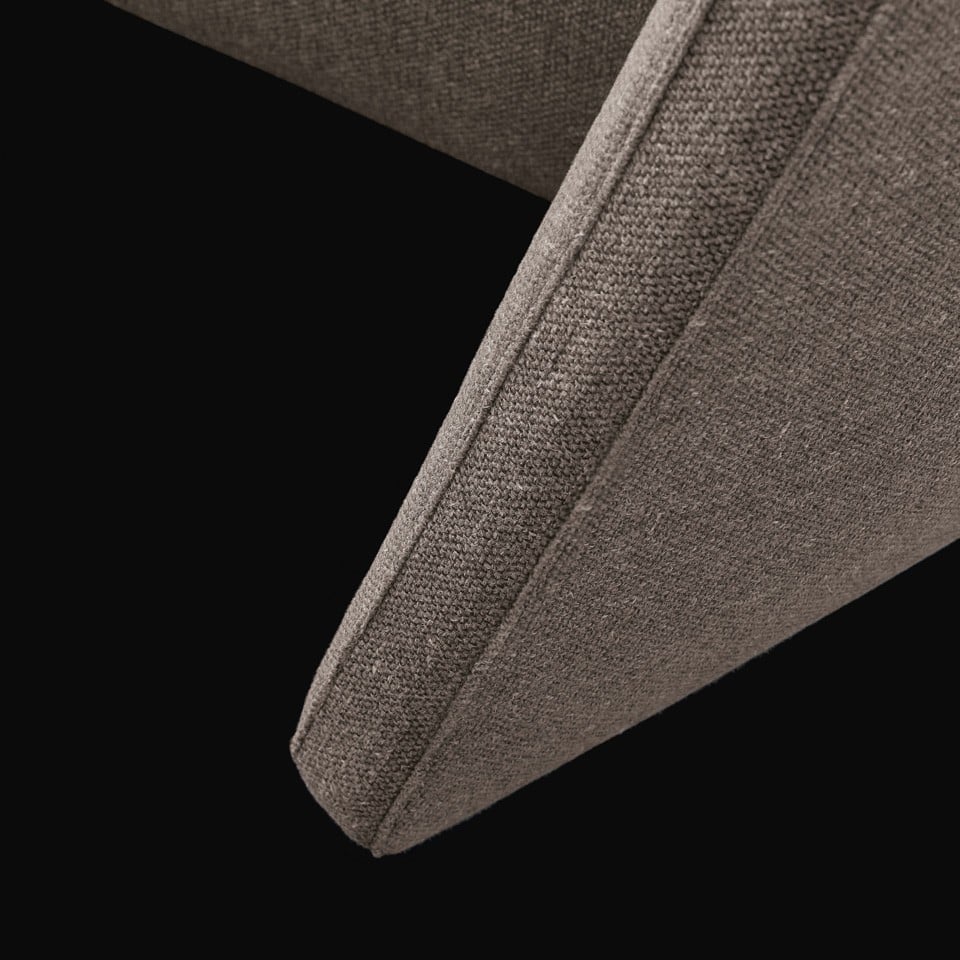

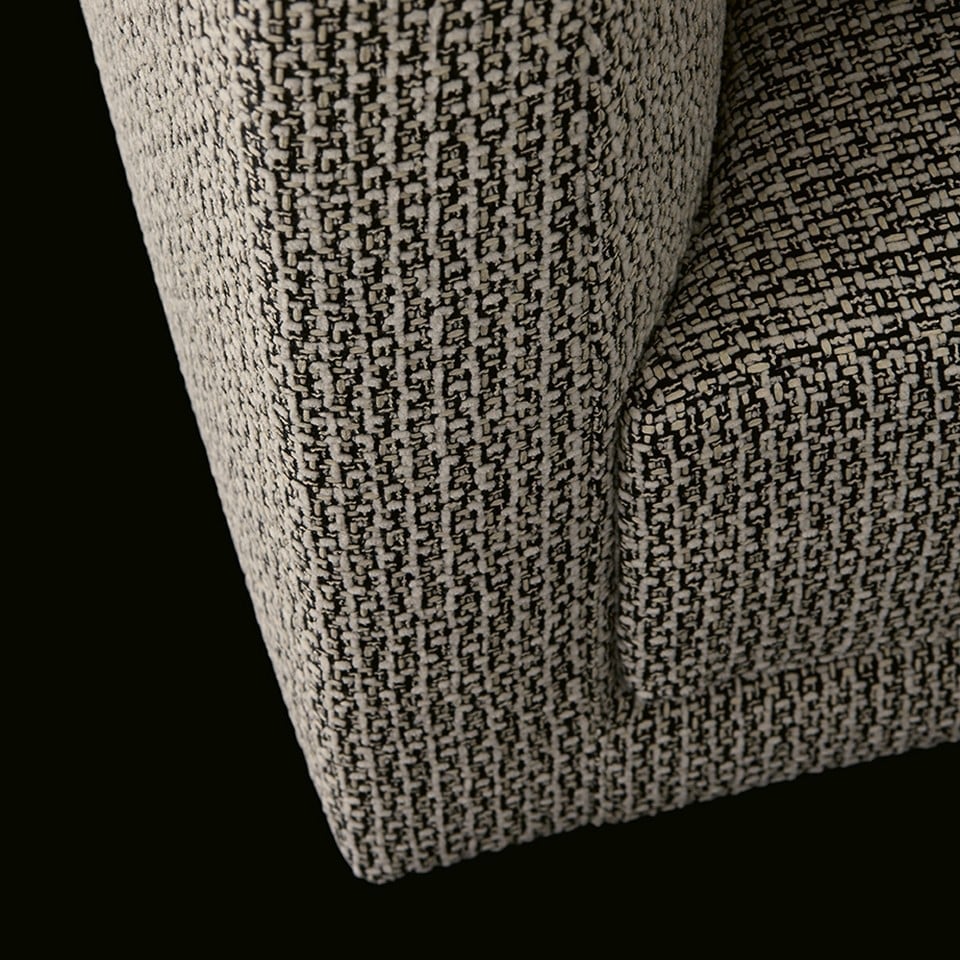

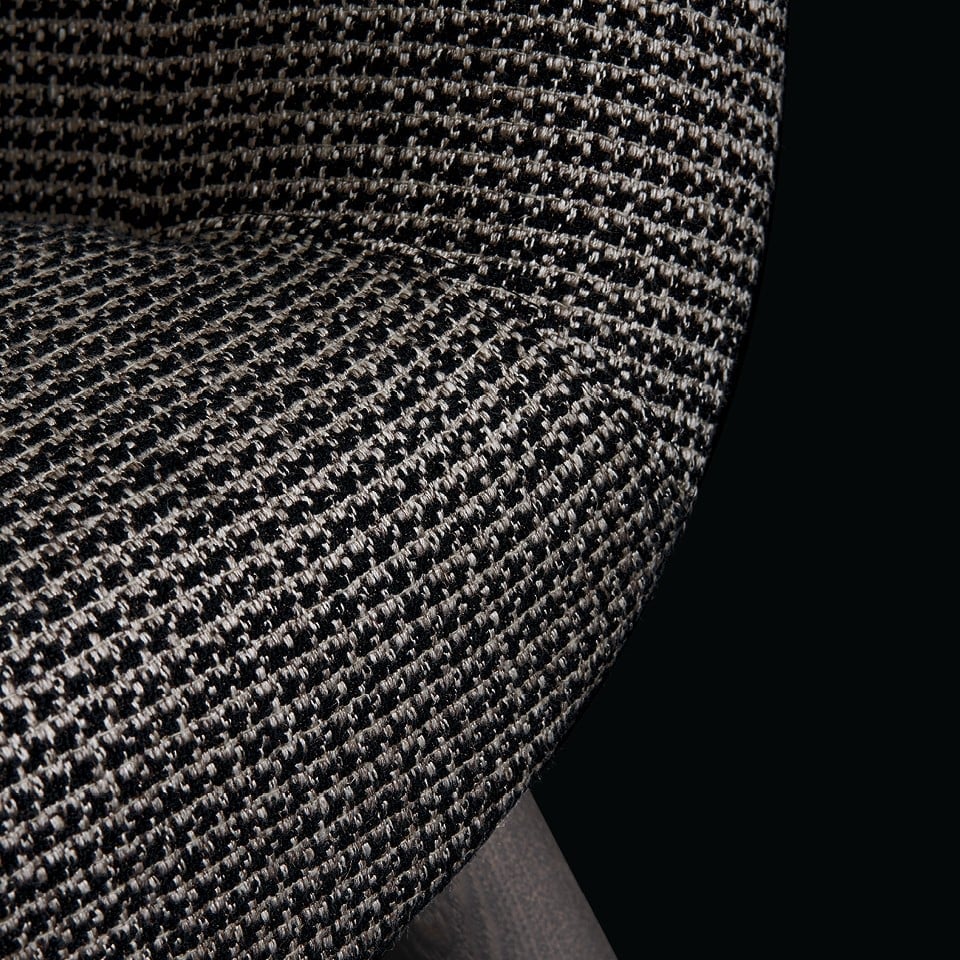

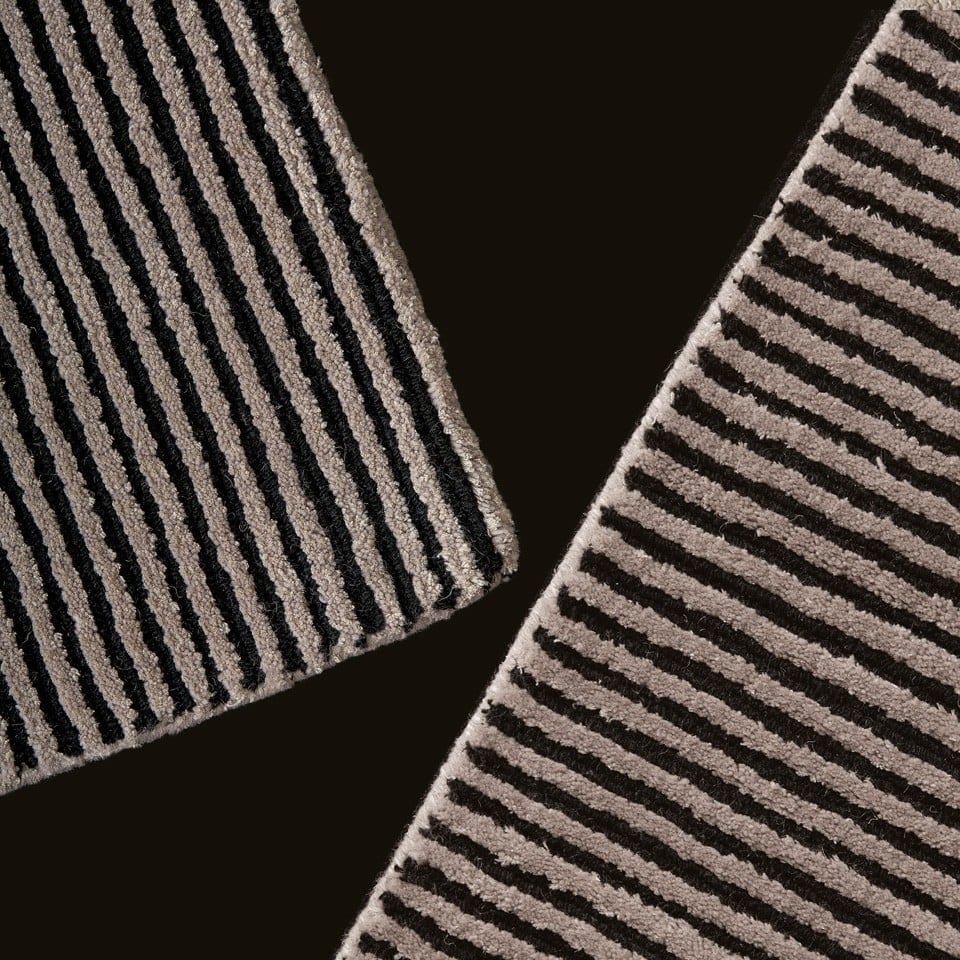

Trevira® (PET)

(Polyethylene Terephthalate), a synthetic fibre derived from macromolecules composed of polyesters and is available in floccules or as smooth or volumised thread. Trevira® is one of the trade names under which it is sold. It is long-wearing, easy to care for and resists fading, humidity and microorganisms.

-

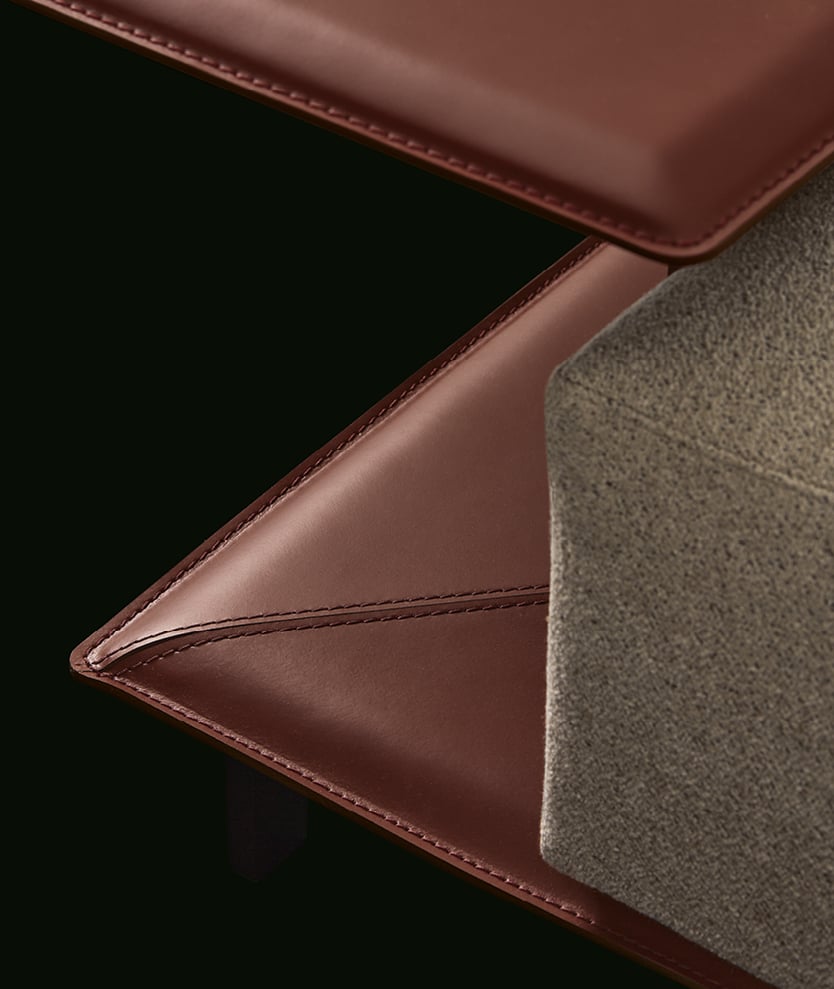

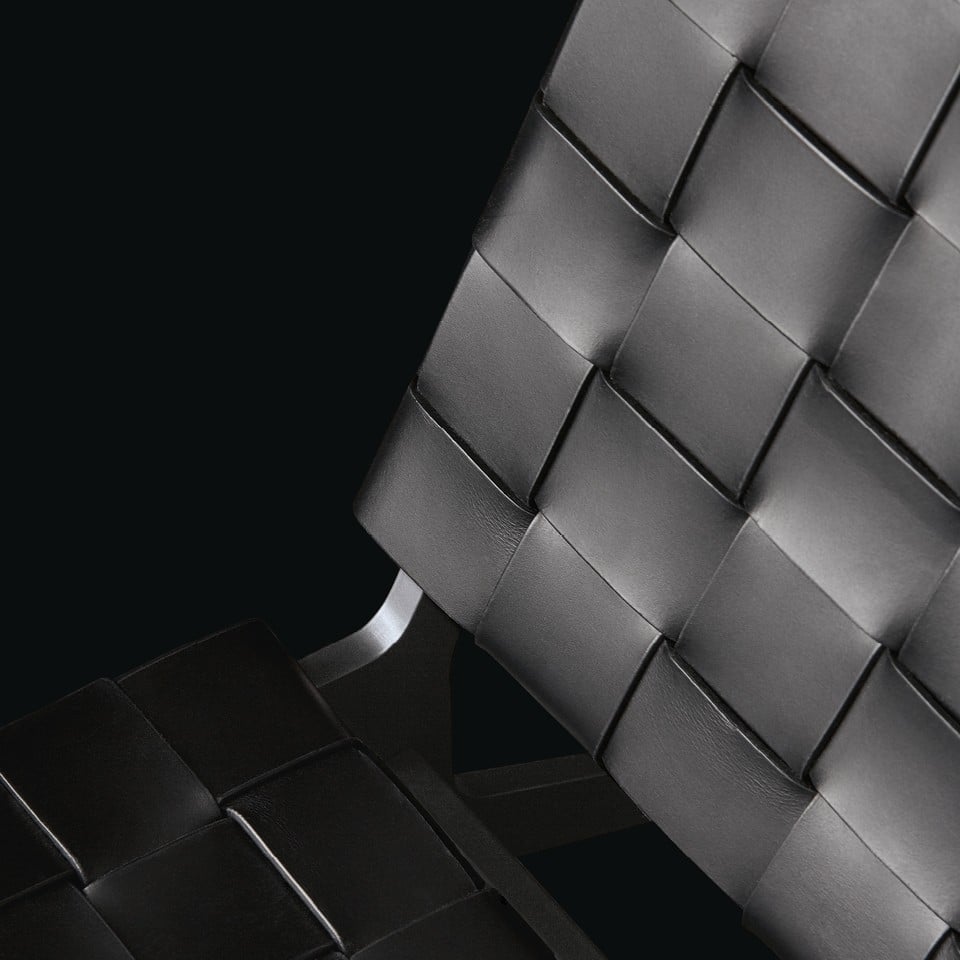

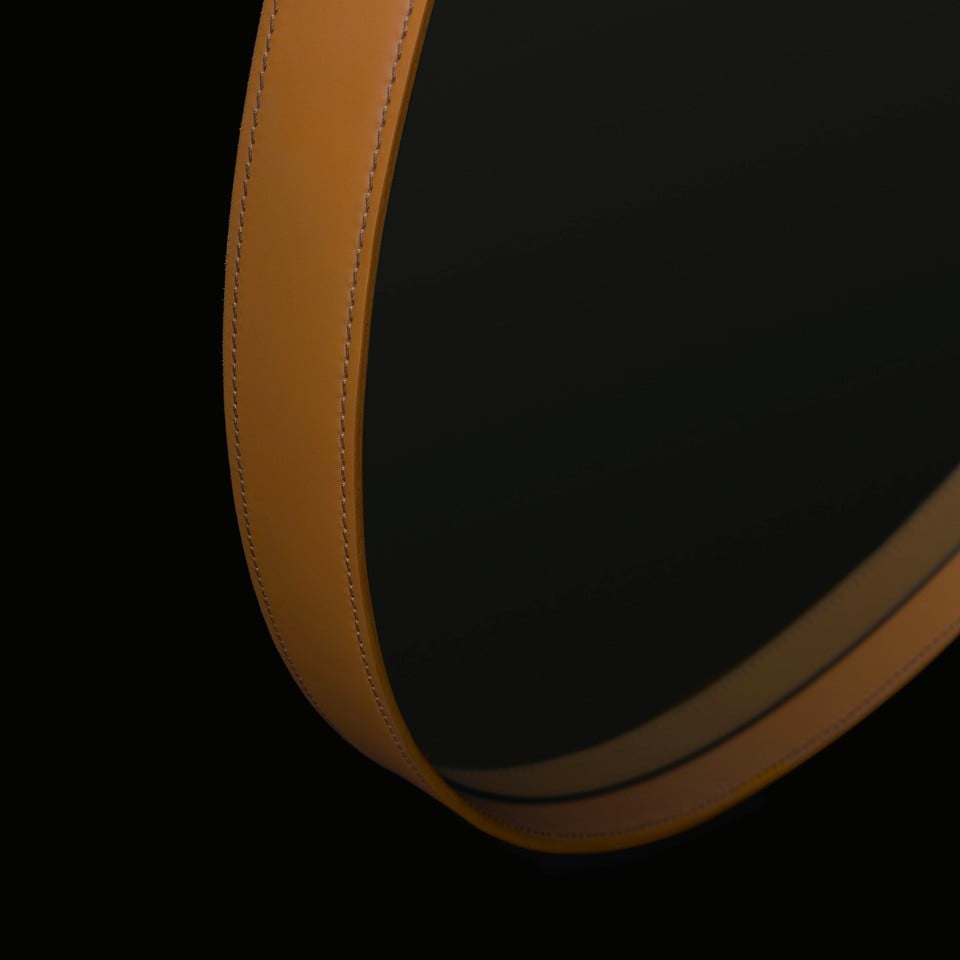

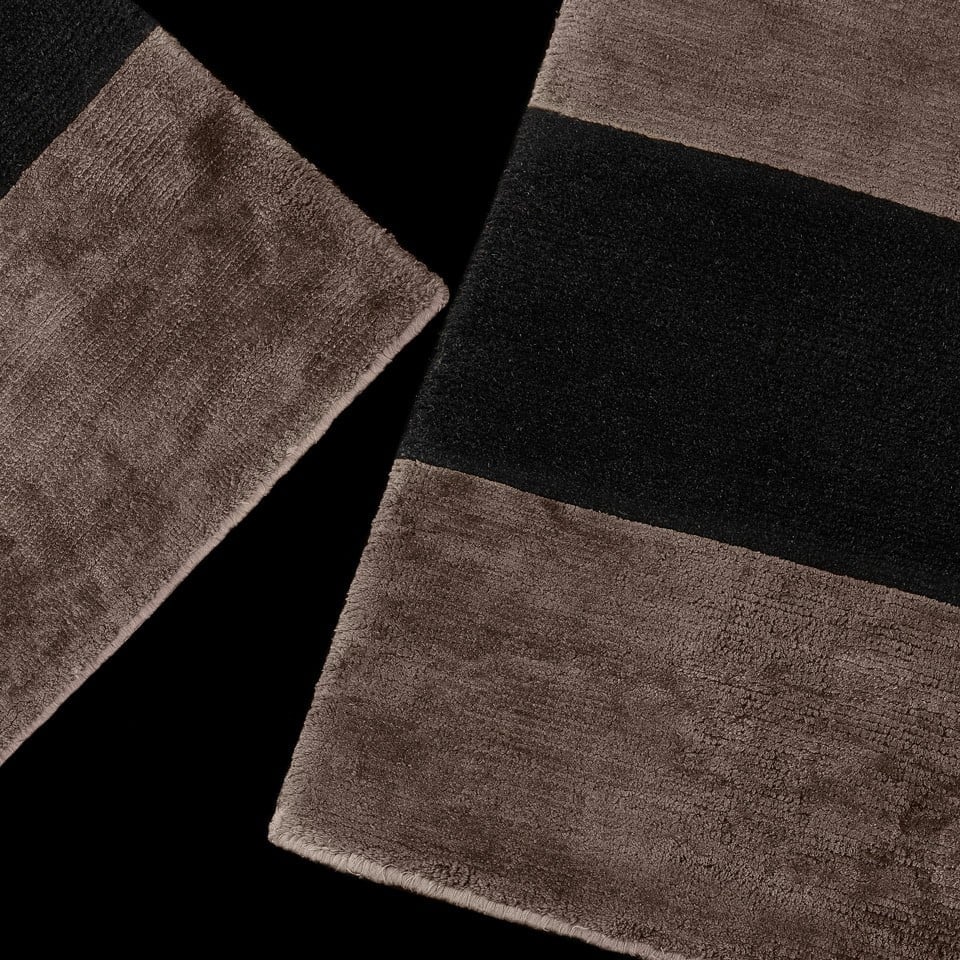

Hide

Hide is a protein material derived from the skins of cattle. Processing is referred to as tanning and consists of eliminating the outermost layer of skin and connective tissue (hypodermis). The most important layer is the dermis, consisting of fibrous fascicles of connective and elastic tissue. The upper portion of the dermis, called the grain, is considered to be the highest grade of leather, called “full grain”.

-

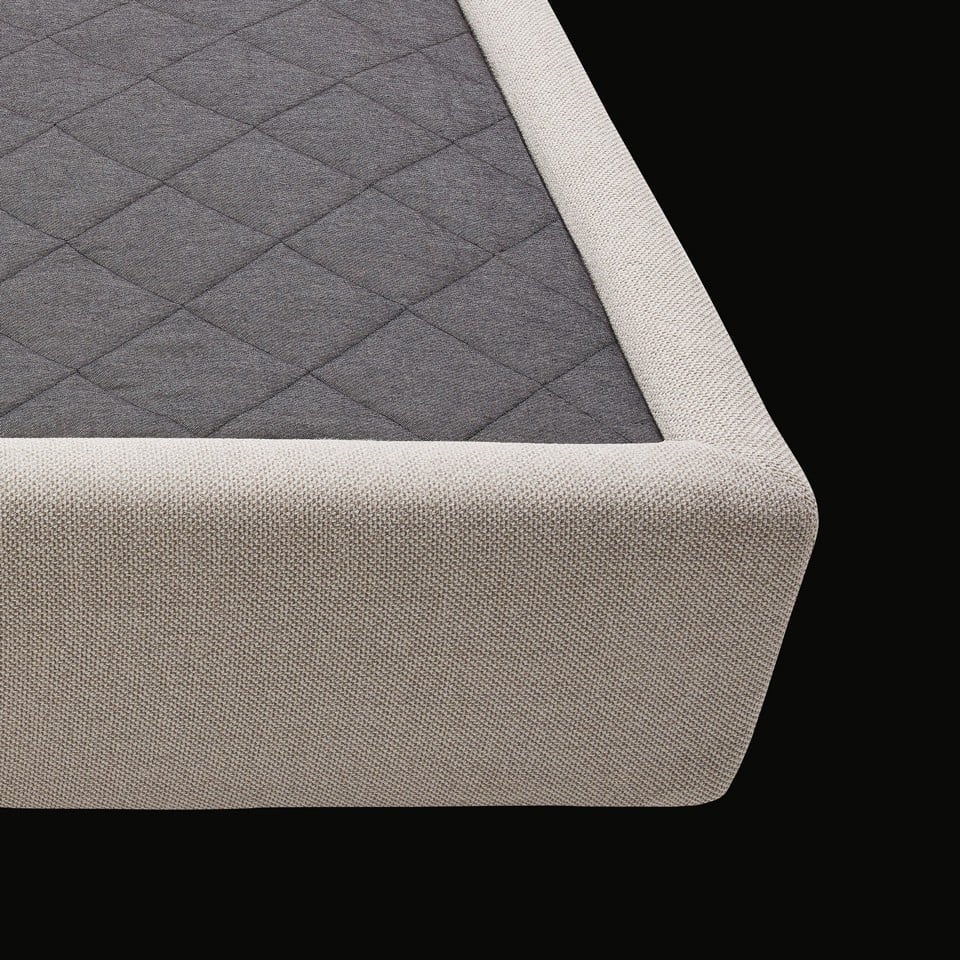

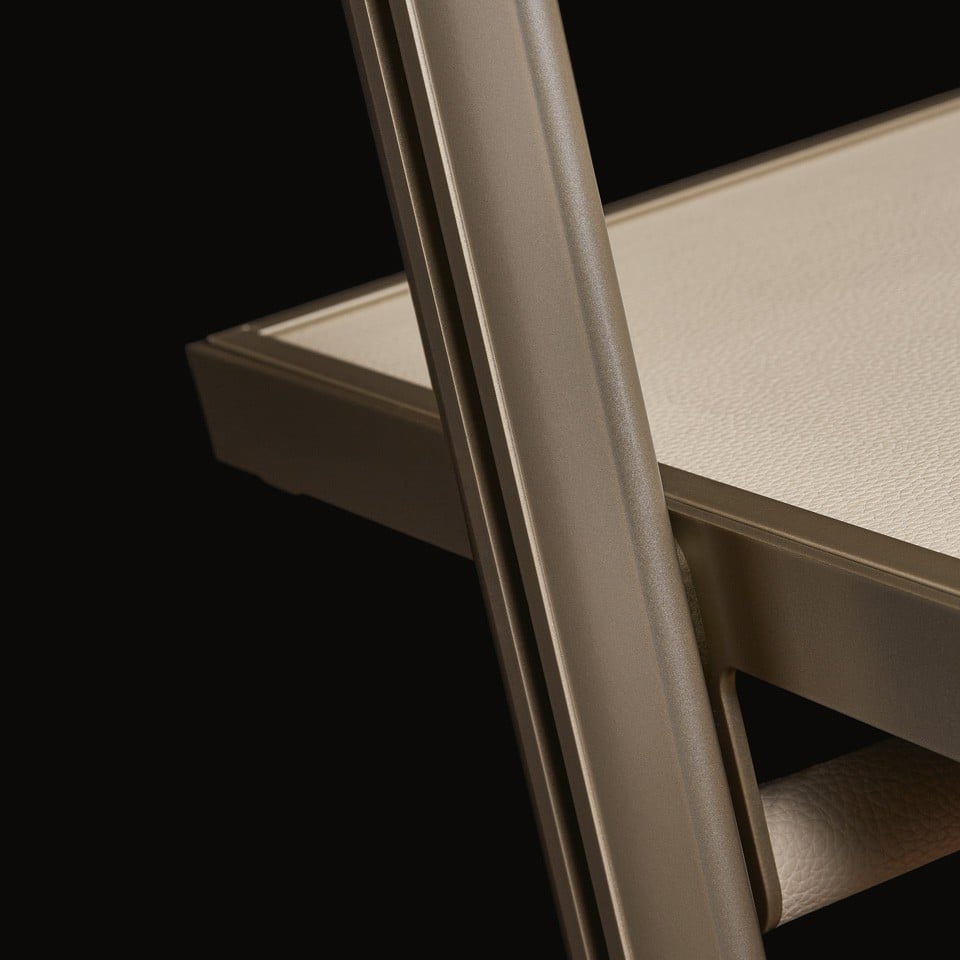

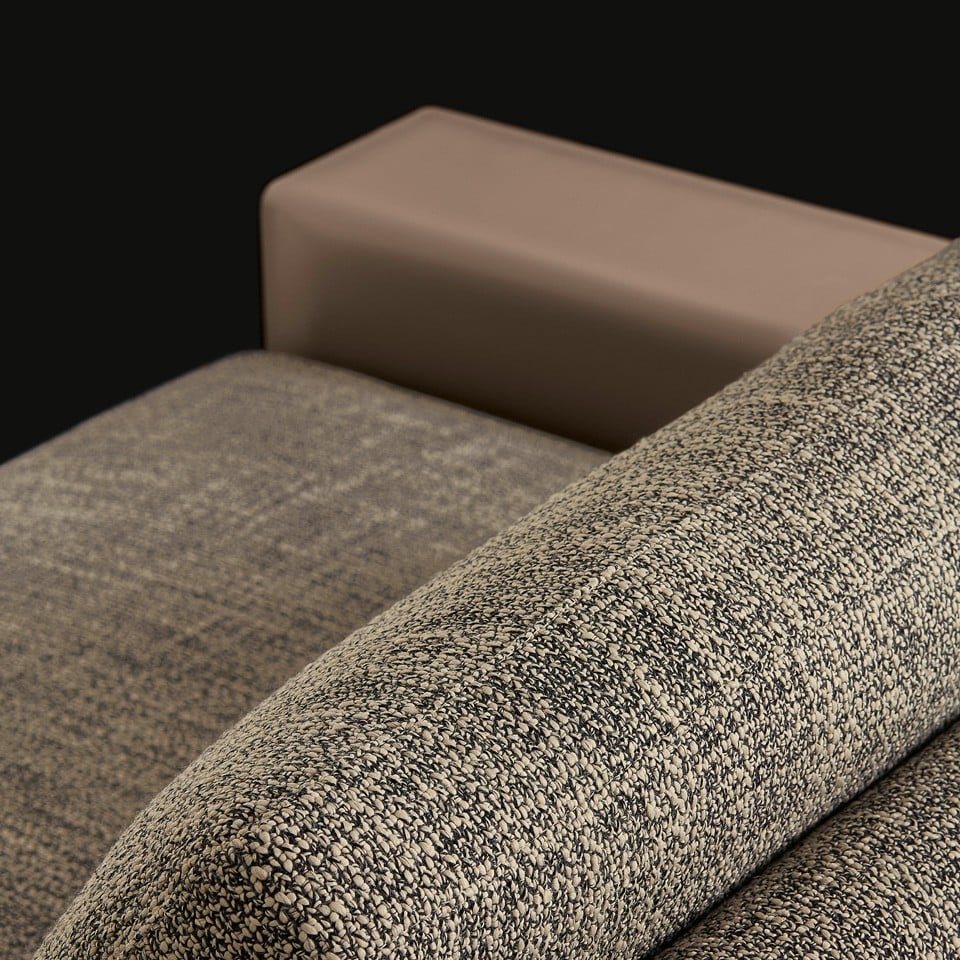

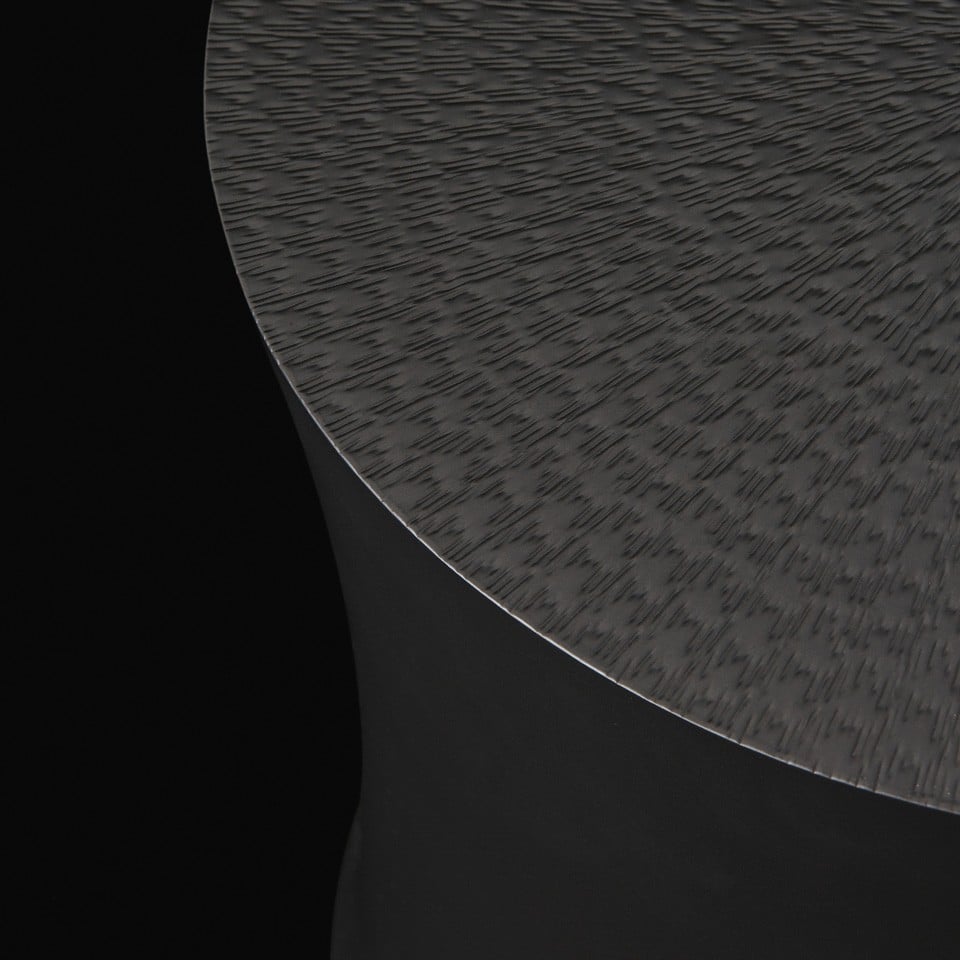

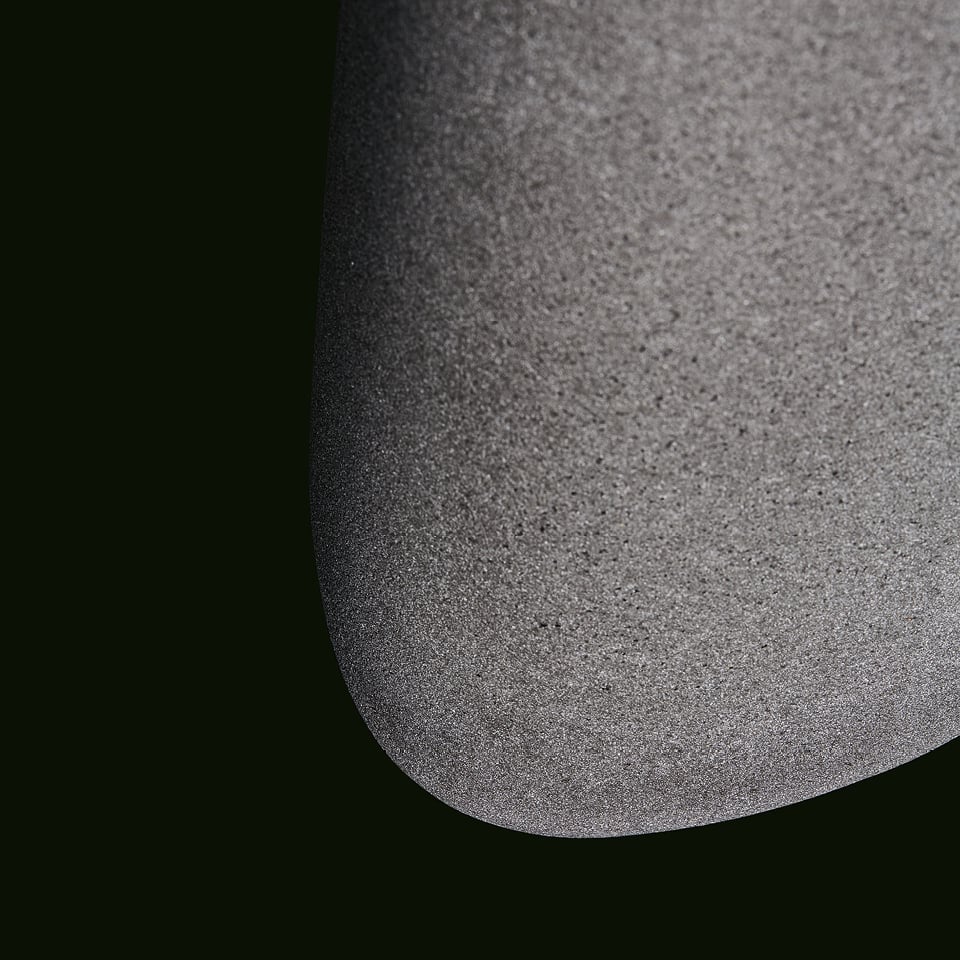

Tecnocover

Tecnocover is a general purpose material, made up of scrap leather, polyurethane and cotton. Scraps from the processing of natural leather are finely chopped and mixed with rubber, latex and other synthetic aggregates. Sheets of tecnocover can undergo various finishing processes, in order to render them as similar as possible to the corresponding natural version. One specifically important process is embossing, whereby the surface is impressed with a specific pattern that imitates the grain of natural leather.

-

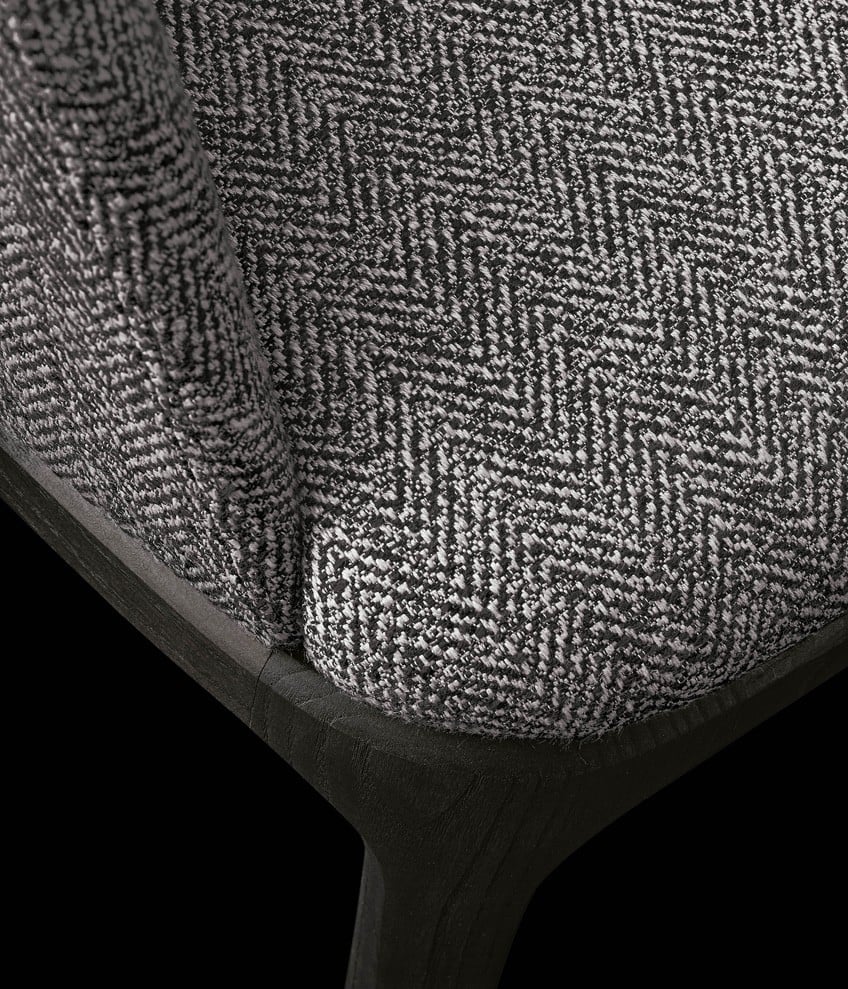

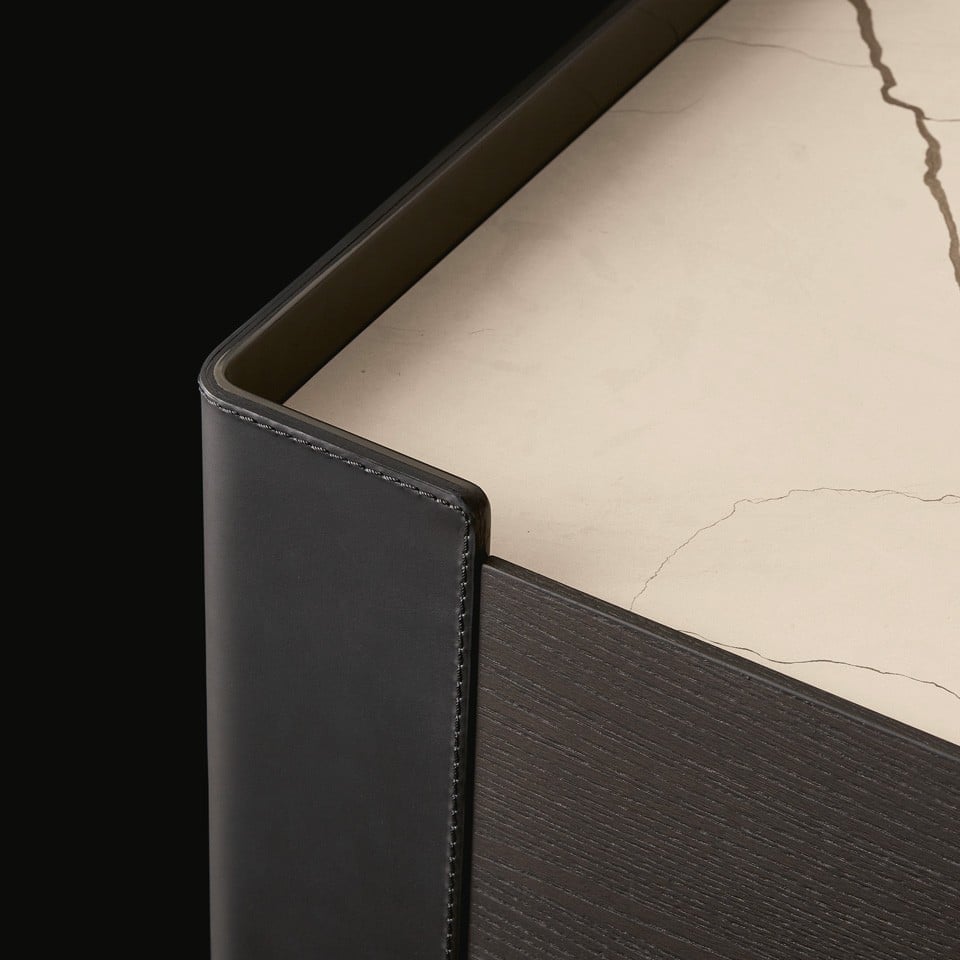

Leather

Leather is a protein fabric derived from cattle and submitted to a tanning process. It is thinner and lighter than hide. General considerations. We give you some information that will help you to understand the characteristics of the leather and hides listed below. The leather derives from the epidermis of the animals that is constituted by various layers and originally has a thickness of around 1 cm. Quality. When speaking of full grain leather, we consider the most superficial layer of the epidermis that maintains the natural characteristics of the grain, veneer and softness (more or less scarred). The dimension of the grain does not determine the quality of the leather, but it derives from aesthetical choices. In the case of more economic hides, the inner layers are used and are manufactured to reproduce the natural characteristics of the leather (grinding and pressure moulding of the grain). Origin. The European origin of the leathers is without doubt to prefer to exotic or overseas origins (which present more defectiveness due to scars and insect bites because of the breeding in the wild). Mineral tanning. The tanning, procedure that wants to preserve the leather from the natural organic decadence, is also used to exalt the softness, the colour, and the brightness of it. It is generally realized with chromium salts; only in the case of high quality leathers a vegetable tanning is realized in order to get the most natural effect. Dyeing. The dye that permits to get all the different colours starting from the natural one is done by immersion of the leathers in dye drums: we always use aniline, through dyeing the whole thickness (to be preferred to the superficial dyeing). Drying. The drying, generally made on frames in ovens, is done naturally at air for the finest leathers. Grain. The natural grain (not embossed) and the absence of grindings (a sort of smoothing) show the use of full-grain leather of a quality that does not need correction and retouch operations.Refinishing. The best final refinishing that then determines the aspect of the leather is the one finished with aniline, with a more natural aspect but also more delicate. The refinishing with polyurethane resins, instead guarantees great uniformity and resistance in the use. Thickness and dimension. A greater thickness determines a better leather and a greater dimension are to be preferred, as you have less waste in use.

-

Leather Spring category P

European origin

Bovine leather

Chromium-salt tanning

Trough dyeing

Vacuum drying

Embossed grain

Grinded

Refinished with polyurethane resin

Thickness 1,0/1,2 mm

Average dimension 4,5/5,0 sqm

-

Leather Colors category S

European origin

Bovine leather

Chromium-salt tanning

Trough dyeing

Thin natural grain

No grindings

Refinished with polyurethane resin

Thickness 1,0/1,2 mm

Average dimension 5,00/5,50 sqm

-

Leather Special category X

European origin

Bovine leather

Chromium-salt tanning

Through dyeing

Thin natural grain

Slightly corrected grain

Refinishing with pigments

Thickness 1,3/1,5 mm

Average dimension 5,00/5,50 sqm

-

Leather Invecchiata category Y

European origin

Bovine leather

Full-grain ox leather

Chromium-salt tanning and vegetable re-tanning

Aniline drum dyed with trough dyeing

Natural drying

Natural grain

No grinding

Refinishing with aniline

Thickness 1,3/1,4 mm

Average dimension 5,00/5,50 sqm

-

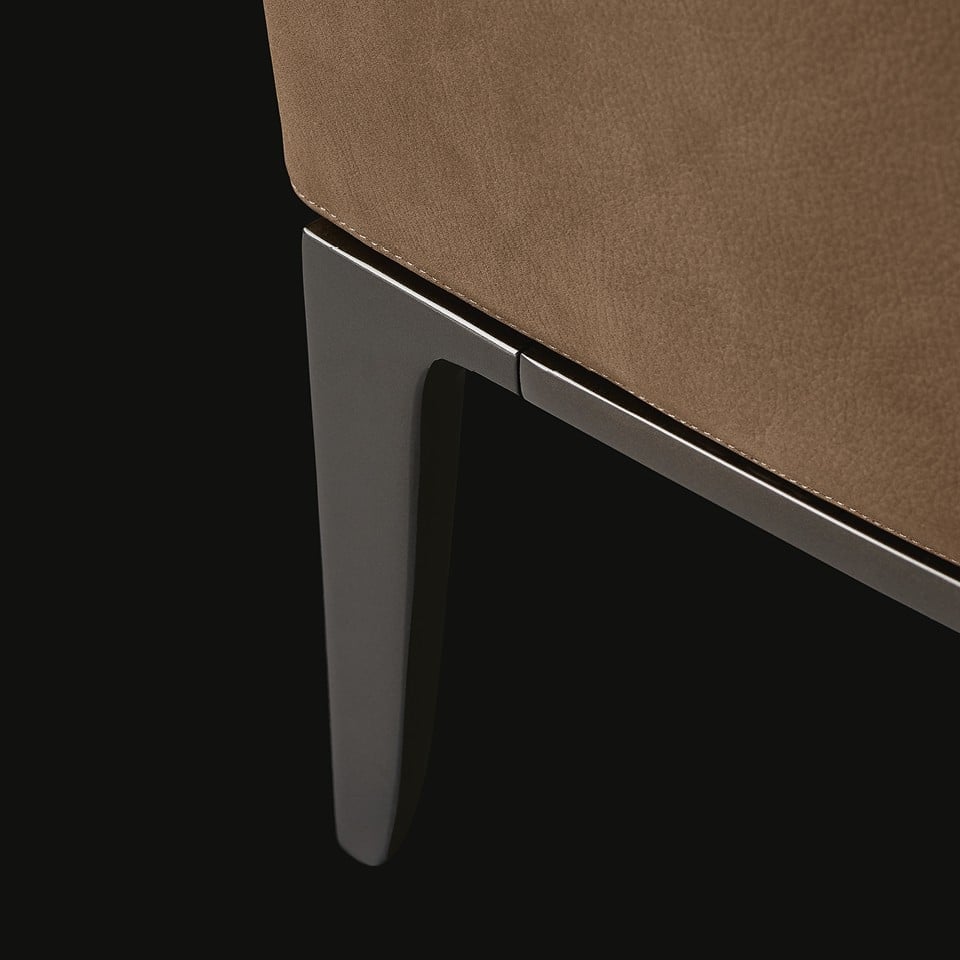

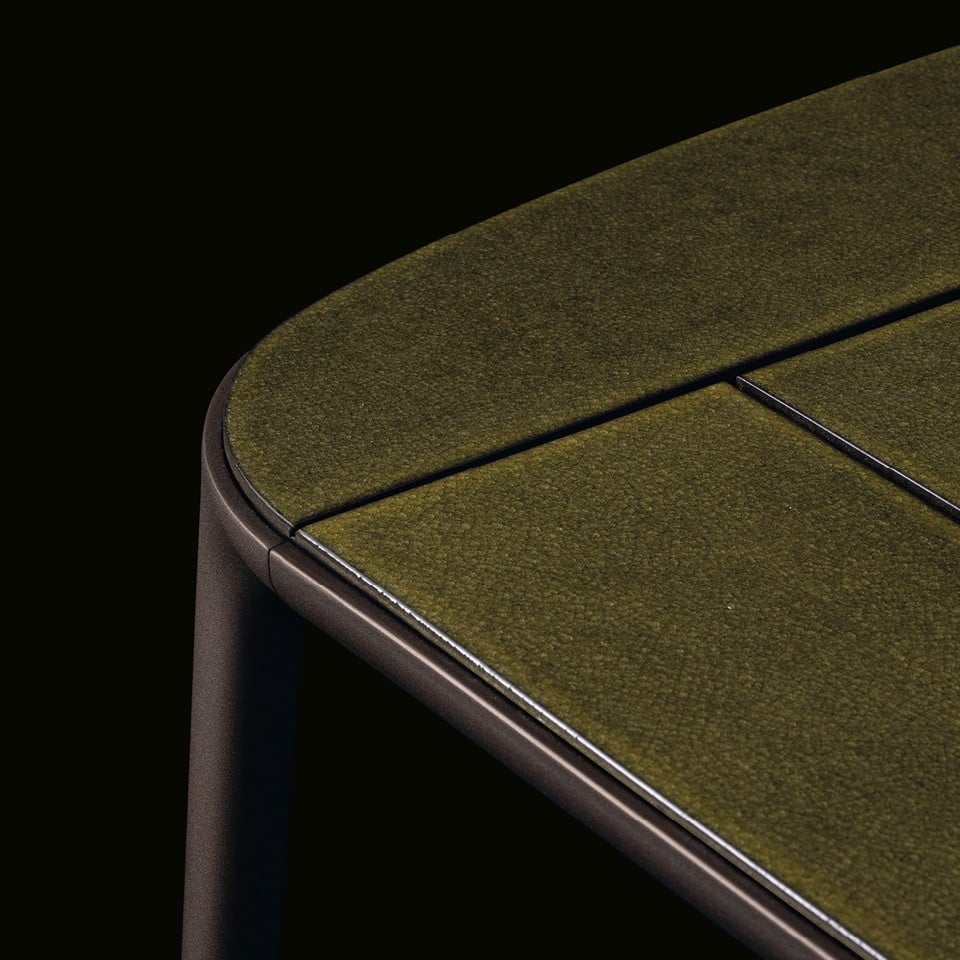

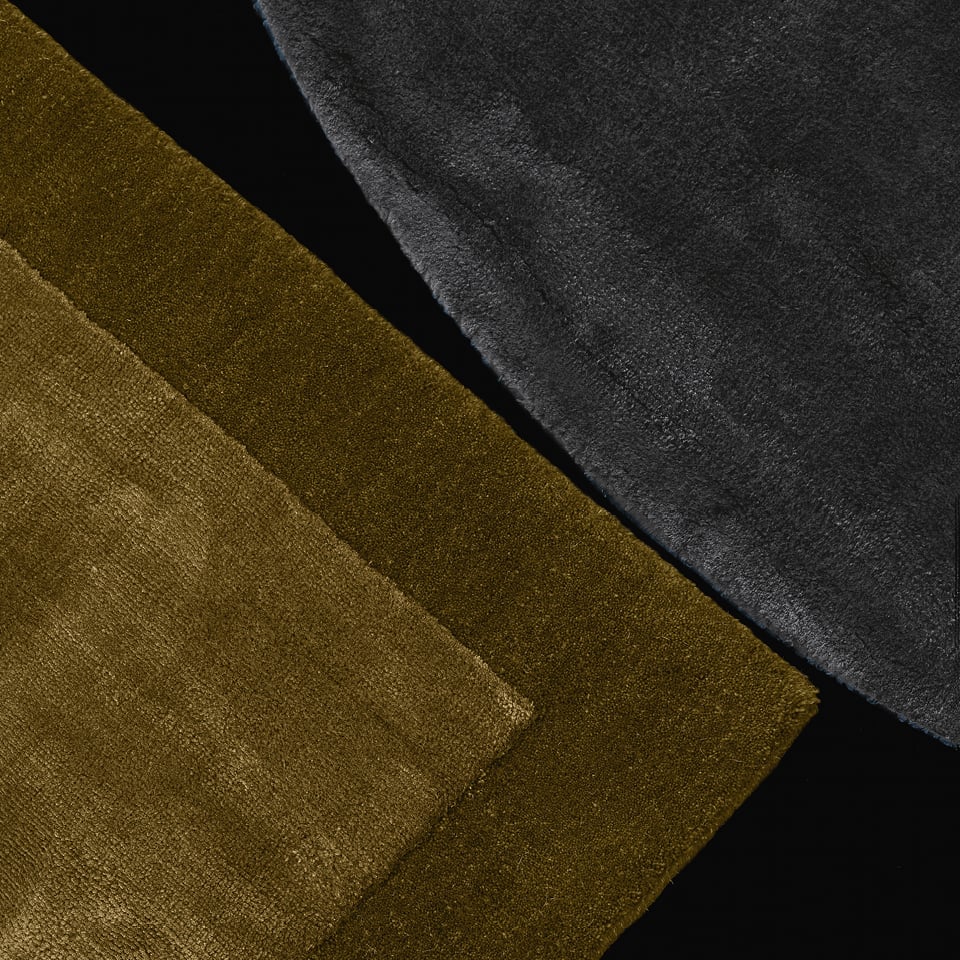

Leather Nabuk category Y

European origin

Bovine leather

Chromium-salt tanning

Aniline drum dyed with trough dyeing

Natural drying

Natural grain

Grinding

3M Scotchgard

Thickness 1,1/1,3 mm

Average dimension 5,00/5,00 sqm

-

Leather Soft category Y

European origin

Bovine leather

Chromium-salt tanning

Aniline drum dyed with trough dyeing

Drying on frame

Natural/full grain

Slight refinishing with water

Thickness 1,5/1,7 mm

Average dimension 5,00 sqm

-

Leather Silk category S

European origin

Bovine leather

Chromium-salt tanning

Through dyeing

Drying on frame

Natural/full grain

Slight refinishing with water

Average dimension c.a. 5,00 sqm

-

Leather Deep category X

European origin

Bovine leather

Chromium-salt tanning

Aniline drum dyed with through dyeing

Drying on frame

Pre-printed natural grain

Refinishing with fine dispersed pigments and waxes

Thickness 1,8/2,0 mm

Average dimension 5,00/5,50 smq